Sunglasses Quality

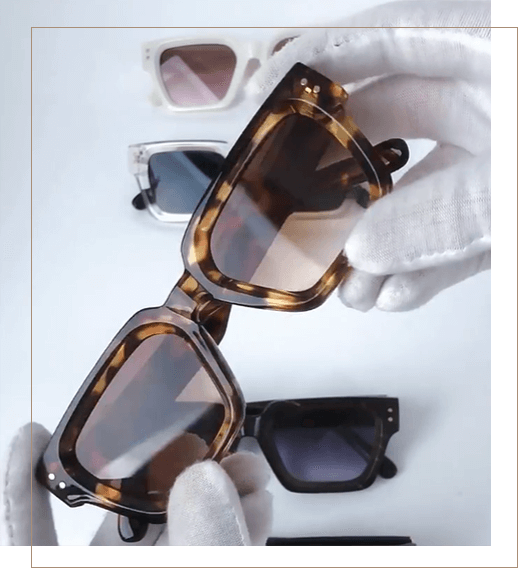

MEET+SHADES combines the tracditional art of sunglasses making with high-tech manufacturing to bring you sunglasses with 100% top quality.

Material? ONLY the Finest.

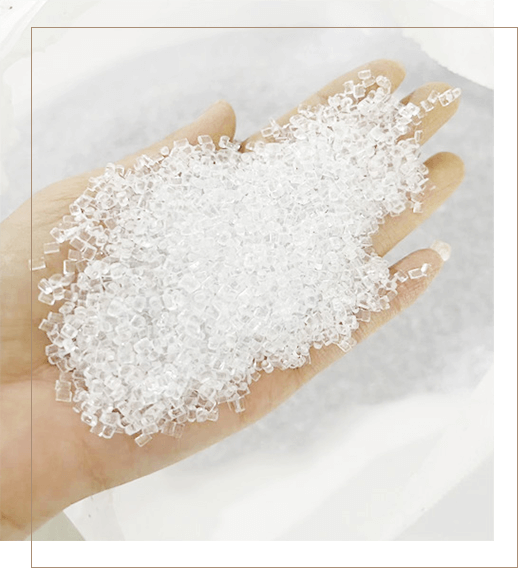

Premium sunglasses is only crafted by high-performance materials. Every component in our sunglasses is the finest,frame ONLY with newest material,second hand material is unacceptable at MEET+SHADES.

At MEET+SHADES,for sunglasses production,we only use:

First and newest polycarbonate material

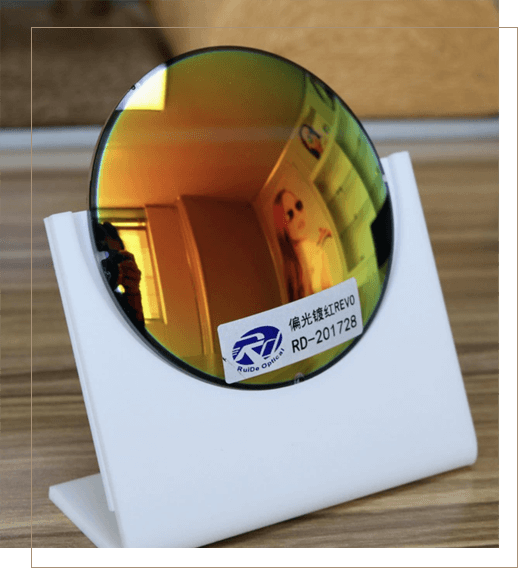

A level PC lenses and TAC polarized lenses

Korean imported machine for REVO coating

All materials will go through strict in-house inspections. Only qualified frame material, decos and lens will be put into mass production.

Our Process

Details For Manufacturing Process

01

Injection

During this process, frames are made with the raw materials in a mold that is loaded on the injection-molding equipment.

02

Polishing

Removes surface imperfections, enhancing smoothness and luster to ensure the frame qualified.

03

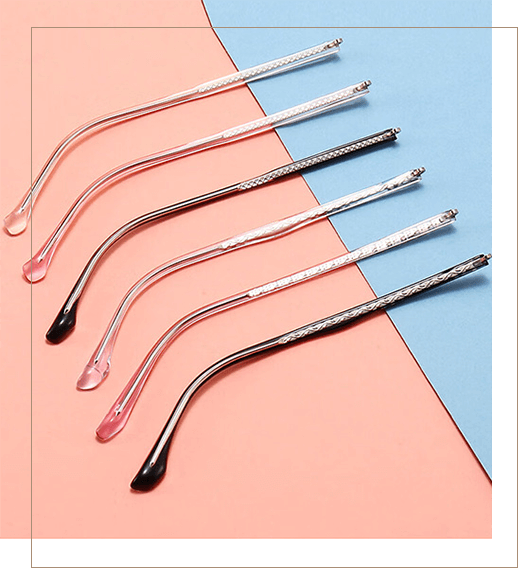

Hinge

Hinge assembly machine works in this process, this process enabling smooth open/close cycles while wearer comfort.

04

Screwing

We use chemical testing passed screws to make frame and temples securely connected and wearing comfortable.

05

LOGO Printing

Screen printing presses,any color or LOGO design is customized,also including hot foil stamping,laser printing and pad printing.

06

Spraying

After blank frames cleaning,we need to print colors on frame to meet customers’ request,shiny,matt or pattern design is acceptable.

07

Inspection

Final check to ensure the sunglasses is well cleaned,logo corrected,frame stable ,function and every part is secured firmly for lasting use.

08

Packing

After QC process,this is last process for shipping,all packing material are customized according to customer’s request.

Our Inspection

Guarantee For Consistent Quality

Frame

- Raw Material

We ONLY use the newest raw material,second-hand is rejected.

- Injection

Germany imported injection machines to ensure every blank frame qualiy.

- Color

Auto spraying and hand spraying to meet differnt request.

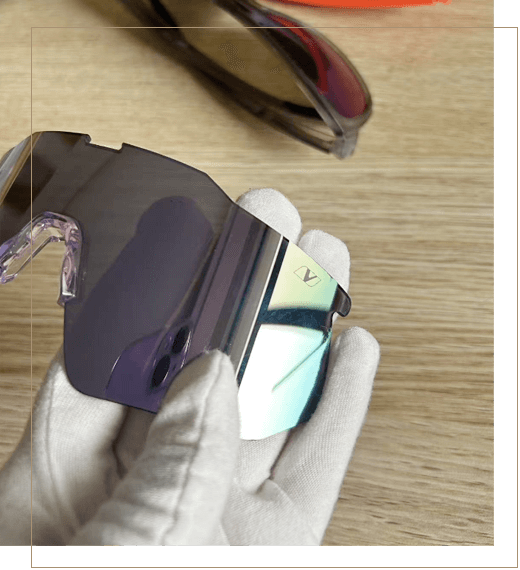

Lens

- Thickness

Measure to see if the lens is as thick as required.

- Color

Check if the color is consistent compare with the lens in the bulk order.

- Quality Level

We only use A level lens for bulk order,B or C is rejected.

Packaging

Color&size

Double check that the packaging material colors and dimensions strictly match the customer’s specifications.

Logo&instruction

Double check that the logo size&color, as well as the insruction details

Surface

Inspect the surface carefully to make sure everything is good without scratch or dust.

Overall Inspection

- Frame

Final check to ensure the sunglasses is clean and every part is secured firmly for last use.

- Logo

Check carefully to see if the logo details is complete&printed as per requirements.

- Package

Double check if the sunglasses is correctly packed in perfect condition